Did you know about container imbalance?

- August 13, 2025

- Blog

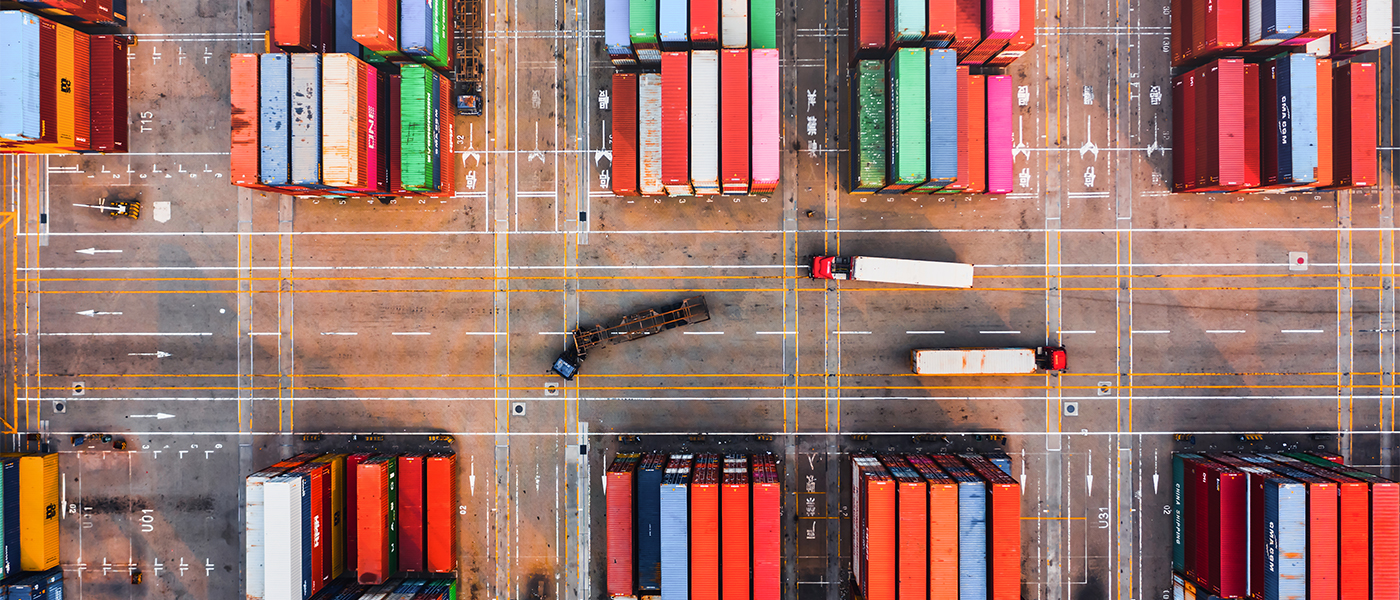

International trade is a vast network that facilitates the transportation of consignments from point A to point B, depending heavily on the shipping industry. However, the industry faces multiple challenges, one of the most pressing is container imbalance or uneven distribution of shipping storage containers. This leads to surging costs and operational inefficiencies for the shipping industry. Moreover, the whole situation disrupts the flow of movement of goods, impacting smooth and timely delivery of goods.

How did this issue come to highlight?

The COVID-19 pandemic brought global attention to the issue of container imbalance as restrictions prohibited container movements, causing the supply to not reach the demand. When the shipping movement comes to an abrupt halt due to issues like a pandemic, the process of movement (export, import and re-positioning of containers) is disrupted, and the issue of container imbalances becomes evident.

What is container imbalance?

A mismatch between demand and capacity is known as container imbalance. In the shipping industry, when there is an inadequate distribution of empty containers in certain regions, it leads to delays and increased costs, including repositioning charges for businesses.

This shortage can be due to:

- Port congestion

- Delay in container repositioning

- Imbalance in trade flow

Why does container imbalance occur?

- When there is excess cargo to ship, but you require more containers

- When excess containers are available, but there is no cargo to ship.

To understand the above point, here is an example, a vessel packed with containers is moved from Point A to Point B, and the same vessel has to return to Point A with no goods, as there are no shipments to be packed from Point B, hence there is no point in return of empty containers, hence they are kept there to fill in at Point B when there are shipments back for the origin. This creates an imbalance, and repositioning of containers occurs.

Being a complex challenge, industry players are working on multiple solutions, such as container pooling, where empty containers are shared by shipping lines to help stakeholders achieve a better global flow of containers.

Global stock of containers

The demand for containers is always there, and the experts believe that the containers in circulation are around 38 million TEUs in circulation, and additionally, a 2 million TEUs worth is under construction annually. Out of this, approximately. 2.5 to 3 million TEUs of containers are almost stored empty. This means around 20% containers handled around global ports are empty containers, highlighting the scale of container imbalance.

Why do empty containers need repositioning?

Trade imbalances

When regions export more than they import or vice versa, it leads to a trade imbalance. The receiving or importing region gets a surplus of empty containers and needs to be repositioned back to the exporting regions to keep up with the demand. Similarly, regions with high imports also have the challenge of a container shortage. Currently, due to the Red Sea crisis, there is a trade imbalance, and this has also led to inflating shipping costs.

Seasonal demand fluctuations

Events like harvest seasons or holiday shopping spikes increase demand for containers in exporting regions. However, if the receiving region has no goods to send back, containers accumulate there. Shipping lines can prepare for such fluctuations by analysing historical trade data and planning ahead to ensure container availability at the right time and place.

Operational inefficiencies

Port congestion is quite common in ports. It can occur due to high traffic volumes along with inefficient cargo handling at ports. Waiting times at some of the ports are quite long, and sometimes it takes 5 days to berth. This delay adds to port charges and contributes to container imbalance.

Container imbalance creates a heavy impact on the shipping sector

Increase shipping rates: The process wherein the empty excessive containers are moved from one location to another location where there are fewer empty containers is called repositioning. This extra cost is transferred to the customer, thus increasing shipping rates.

Shipping delays: While these empty containers are being repositioned, the goods waiting at ports face delays. This delay disrupts the supply chain, delaying the transportation and deliveries of goods to stores or customers.

Environmental effect: As the containers are moved frequently for repositioning from one place to another, it increases fuel consumption and produces harmful carbon emissions. The excess movement also adds to the increase in the maritime company’s carbon footprint.

Supply chain disruption: With containers are not available at their designated regions at the right time, it causes disruption in supply chain logistics. Ports become overcrowded and ships transit with empty slots, creating logistics chaos. The disturbances impact the shipping business and make it inefficient.

What should be the management strategies to avoid container imbalance?

Forecasting and Planning: As the global shipping market keeps on fluctuating, companies need to be proactive. To keep a tab on the market changes, data analytics tools can be used to understand the container requirements from the past data history, which can help plan for the sudden shortages, repositioning and ensuring that containers are available when needed.

Tech Solutions: Tech is always reliable with smart solutions for all the complexities of container imbalance. 20Cube’s digital portal offers a centralised container management system that provides real-time tracking and visibility. With exact data on container positions, companies can make informed decisions to reposition containers where they are needed most.

These digital platforms reduce costs, increase efficiency and lead to smooth operations of the container business across global trade routes.